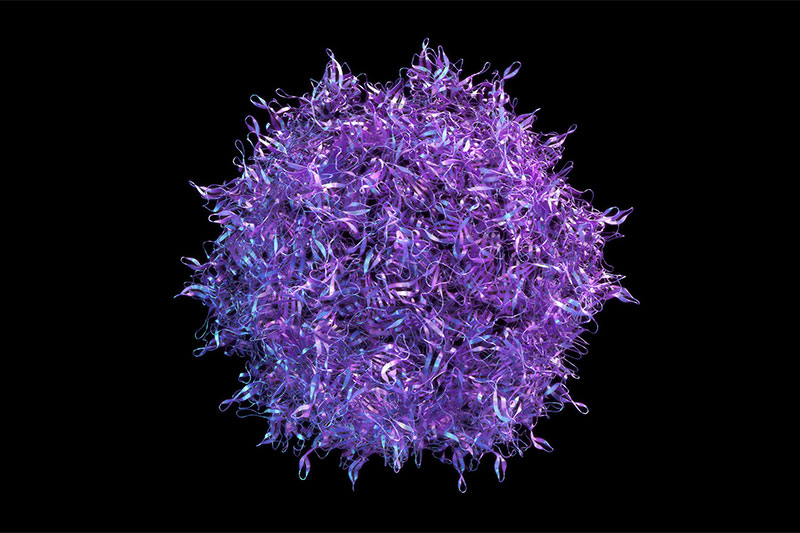

Pioneering high-yield cell suspension line

Long before many AAV manufacturers existed, we recognized a universal need that crosses all AAV therapeutics – the need for a process that increases production and lowers manufacturing cost. In 2010, we introduced Pro10™, a cell line for generating novel AAV therapeutics. Our system uses a human embryonic kidney (HEK)-based cell line in serum-free suspension media to develop and produce AAV vectors.

Pro10™ was one of the first HEK293 based suspension cell line to achieve high-yield AAV manufacturing without using any human or animal derived by-products to grow in bioreactors. This results in highly efficient and scalable AAV vector manufacturing.

Pro10™ is used in AskBio’s Viralgen manufacturing facilities and is licensed by leading global biopharma companies.

- Produces high yields of AAV vectors

- Universal manufacturing system that produces several serotypes and chimeric capsids packaging single-stranded and self-complementary genomes

- Cost advantages with transient transfection of a patent-protected cell line

- Scalable production from benchtop to bioreactor allowing for early assessment of vectors enabling rapid scale-up